Before you go an buy a vision system, you need to do your homework. Lighting is critical to the robustness of any vision system, even those with geometric location capabilities. The correct optics is also important, since many people will buy an expensive high resolution cameras and then put a low resolution lens on the camera. Interface is also very important. USB is cheap but almost needs to sit next to the computer due to cable length issues.

What I am trying to say is, give us a call first before you make a mistake. We can guide you through the process at no charge. We want you as a customer, so hopefully if we give you good advice you will consider us for your current or your next project.

We are the industrial vision system experts. We have developed vision systems for all sort of robotic and inspection purposes.

Here are a few of our projects:

- Extremely high resolution total glass inspection system.

- Extremely high resolution user friendly line scanning inspection of clear glass for defects and chips using a low quality conveyor system.

- High resoluition glass trademark inspection system capable of finding missing portions of a letter.

- High resolution and extremely accurate glass location system for robotic squaring using just one edge of the glass.

- Low resolution low cost target location for furnace loading.

- Drill hole inspection for chips in glass.

- Bar Code reading at 200 parts/min.

- Bottle label inspection at 200 parts/min.

- Vision guided glass grinding system, to reduce training time from 60 minutes to 5.

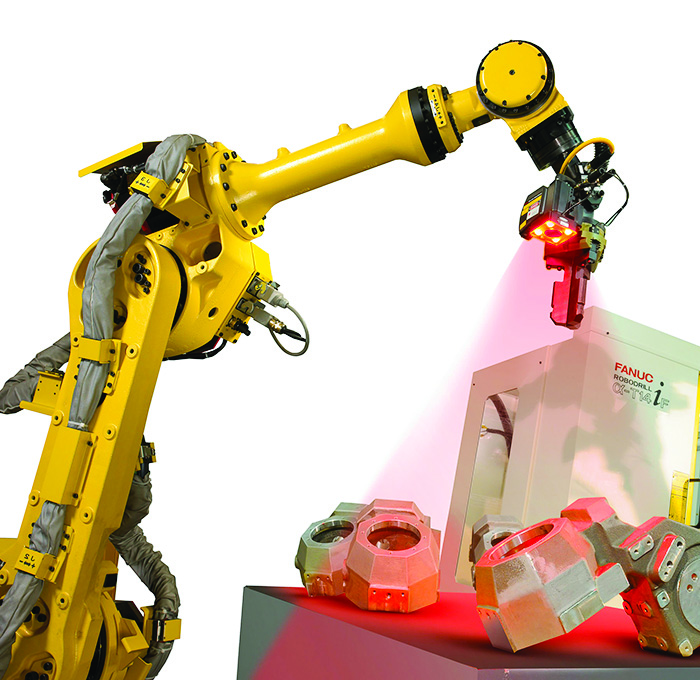

- Location and inspection of brake components.

- Glass edge chip inspection using line scanning and servo motors to inspect edge quality all away around the glass surface.

- Vision location of Plastic pin holders for robotic loading.

We are experts in Halcon, Hexsight and Cognex systems. We invite you to goto these sights and see what these systems can do for you.